TL,DR:

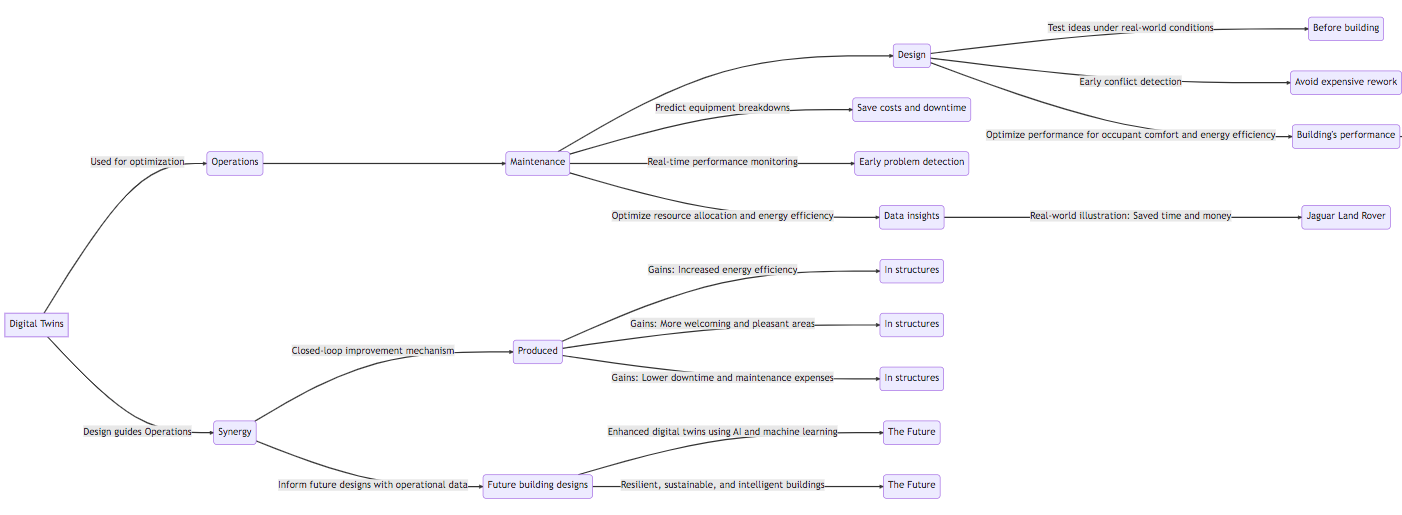

Digital twins are computer-generated images of actual buildings that are used to optimise

operations, maintenance, and design using real-time sensor data.

Advantages for Optimising Design

- Before building, test and refine ideas under real-world conditions (lighting,

energy consumption, etc.). - Early detection of conflicts between architectural elements will help you avoid

expensive rework. - A building’s performance should be optimised for things like occupant comfort and

energy efficiency. - Real-world example: Doosan Heavy Industries & Construction increased

the efficiency of their wind farm by 15% by using a digital twin.

Advantages for Optimising Maintenance and Operations:

- Predict equipment breakdowns to save costs and downtime through proactive

maintenance. - Real-time building performance monitoring helps you see problems early and take

prompt action. - Utilise data insights to optimise resource allocation and energy

efficiency. - Real-world illustration Using a digital twin, Jaguar Land Rover was able

to save time and money by identifying clashes early on in the design

process

The Synergy : Design guides Operations and Vice Versa

- Future building designs are informed by operational data derived from the digital

twin. - A closed-loop mechanism for ongoing improvement is therefore produced.

Gains:

- Increased energy efficiency in structures.

- Areas that are more welcoming and pleasant.

- Lower downtime and maintenance expenses.

The Future:

- Enhanced digital twins for complex systems using AI and machine learning.

- Resilient, sustainable, and intelligent buildings.

Ways to Begin:

- Invest in knowledge and infrastructure for data.

- Create and utilise digital twins for your smart buildings by collaborating with

Pratiti Technologies.

Table of Content:

Introduction

The global smart building market is experiencing explosive growth, projected to surge from USD 96.96 billion in 2023 to a staggering USD 568.02 billion by 2032, exhibiting a robust CAGR of 21.8%. This rapid growth highlights the rising need for well-designed and functional structures. The digital twin, a cutting-edge technology that provides a virtual duplicate of actual assets, is at the vanguard of this change. Digital twins, which replicate the intricacies of smart buildings and factories, offer unequalled prospects for optimising design, operations, and overall performance. This progress will propel the sector towards a future characterised by extraordinary efficiency and sustainability. In this article, we will understand how this revolutionary technology works in optimising design and operations in these spaces.

Understanding Digital Twins

In essence, a digital twin is an electronic copy of a real asset, like a factory or building. Envision possessing an intricate digital replica of your structure that is continuously updated with actual data. This digital equivalent functions as a dynamic, living model that is amenable to simulation, analysis, and optimisation.

The technique of creating a digital twin is quite precise. Using Computer-Aided Design (CAD) or Building Information Modelling (BIM) data, the physical asset’s design and structure are first captured. This offers a blueprint that is static. Then, the magic happens when sensors are deployed throughout the physical space to collect real-time data on everything from temperature and humidity to energy consumption and equipment performance. This data is continuously fed into the digital twin, transforming the static model into a dynamic, living representation of the physical asset.

Optimising Design with Digital Twins

With the ability to create virtual duplicates that mimic real-world situations, digital twins are revolutionising the design process. This makes it possible for engineers and architects to test and modify ideas before construction begins, significantly boosting performance, sustainability, and efficiency.

A. Modelling and Adjustment

With the aid of digital twins, it is possible to create incredibly realistic virtual worlds that replicate actual situations. Through the process of creating a digital environment that mirrors the real world, designers can:

1. Simulate Real-World Conditions:

- Lighting: Take into account factors like window size, sun angle, and shading devices while simulating artificial and natural light distribution.

- Energy Consumption: Calculate how much energy is used by ventilation, lighting, heating, and cooling systems in various climates.

- Water Usage: Model plumbing system water consumption trends while considering fixture efficiency and occupancy.

- Occupancy and Foot Traffic: To improve layouts and circulation, model human movement and density inside areas.

- HVAC Performance: To guarantee optimal interior comfort and energy efficiency, mimic the behaviour of HVAC (heating, ventilation, and air conditioning) systems.

2. Optimise Building Performance:

These simulations provide invaluable insights for optimising:

- Energy Efficiency: Identify opportunities for energy reduction through factors like building orientation, insulation, glazing, and HVAC system design. For instance, a digital twin can reveal how different façade materials impact energy consumption throughout the year.

- Lighting Design: Optimize daylighting and artificial lighting placement for visual comfort and energy savings. By simulating daylight penetration and glare, designers can fine-tune lighting systems accordingly.

- Equipment Layout: Evaluate the impact of equipment placement on workflow, accessibility, and maintenance. For example, simulating material flow in a factory can optimise equipment layout to minimise bottlenecks and maximize productivity.

Real-World Implementation: Doosan Construction & Heavy Industries

To understand this better, let’s take a look at the Doosan Heavy Industries & Construction example to see the power of digital twins in action. Doosan collaborated with Bentley Systems and Microsoft to create a thorough digital twin of its wind farms to increase the wind turbines’ efficiency.

Doosan produced a virtual version of their wind farms by utilising Azure Digital Twins and Azure IoT Hub, which are driven by NVIDIA-accelerated AI. This virtual counterpart facilitates:

- Maximising Energy Production: Doosan can optimise turbine location, orientation, and operation for optimal energy output by modelling wind patterns, turbine performance, and grid conditions.

- Predictive Maintenance: Doosan can detect possible equipment faults before they happen, cutting downtime and maintenance costs. Predictive maintenance is made possible by real-time sensor data input into the digital twin.

- Remote Control and Monitoring: Doosan can monitor wind farm operations remotely thanks to the digital twin, which makes it easier to identify abnormalities, maximise performance, and quickly address problems.

The digital twin project by Doosan has produced outstanding outcomes. Because of improved scheduling, predictive maintenance, and fewer on-site inspections, the organisation has claimed a 15% decrease in operating and maintenance expenditures. Additionally, Doosan is now able to make data-driven decisions thanks to the digital twin, which has enhanced wind farm performance overall and increased energy output.

B. Clash Detection & Cost Savings

Digital twins are particularly good at spotting possible clashes in a building or industrial design, such as those involving structural components, mechanical systems, and electrical installations. Clashes may be identified early in the design process by modelling the real world in a virtual space, which helps to avoid expensive mistakes during construction.

1. Early Identification and Prevention:

- Pre-construction Clash Detection: By allowing for a thorough examination of the complete building model, digital twins make it possible to spot any clashes between various building systems. Time and money may be saved by modifying the design before construction starts thanks to this proactive approach.

- Construction Phase Clash Management: To detect and resolve clashes on-site, digital twins can be updated with real-time data even while work is underway. Discrepancies may be quickly identified and fixed by comparing the as-built model with the digital twin, reducing the need for rework.

2. Efficiency and Cost Savings:

- Decreased Rework: By locating and addressing clashes early on in the design process, a great deal less expensive rework is required while building.

- Accelerated Construction: Construction may go more quickly by reducing on-site problems, which will enable the project to be completed on time or even ahead of schedule.

- Enhanced Quality: By guaranteeing the precise and effective integration of many building systems, proactive clash detection helps produce a final product of a better calibre.

Real-World Implementation: Doosan Construction & Heavy Industries

To understand the power of digital twins in action, let’s take a closer look at the example of Doosan Heavy Industries & Construction. Doosan collaborated with Bentley Systems and Microsoft to create a comprehensive digital twin of its wind farms to enhance the efficiency of wind turbines.

Doosan produced a virtual version of their wind farms by utilising Azure Digital Twins and Azure IoT Hub, driven by NVIDIA-accelerated AI. This virtual counterpart facilitates several key improvements:

- Maximising Energy Production: By modelling wind patterns, turbine performance, and grid conditions, Doosan can optimise turbine location, orientation, and operation for optimal energy output.

- Predictive Maintenance: Real-time sensor data input into the digital twin allows Doosan to detect potential equipment faults before they occur, reducing downtime and maintenance costs.

- Remote Control and Monitoring: The digital twin enables Doosan to monitor wind farm operations remotely, making it easier to identify abnormalities, optimise performance, and quickly address issues.

The digital twin project by Doosan has led to outstanding outcomes. The organisation has reported a 15% decrease in operating and maintenance expenditures due to improved scheduling, predictive maintenance, and fewer on-site inspections. Additionally, the digital twin has enhanced overall wind farm performance, leading to increased energy output and better data-driven decision-making.

B. Clash Detection & Cost Savings

Digital twins are particularly effective at identifying potential clashes in building or industrial design, such as those involving structural components, mechanical systems, and electrical installations. By modelling the real world in a virtual space, clashes can be identified early in the design process, helping to avoid costly mistakes during construction.

1. Early Identification and Prevention:

- Pre-construction Clash Detection: Digital twins enable a thorough examination of the entire building model, allowing for the detection of any clashes between different building systems. This proactive approach can save time and money by allowing design modifications before construction begins.

- Construction Phase Clash Management: Digital twins can be updated with real-time data during the construction phase to detect and resolve clashes on-site. By comparing the as-built model with the digital twin, discrepancies can be quickly identified and rectified, reducing the need for rework.

2. Efficiency and Cost Savings:

- Decreased Rework: Early detection and resolution of clashes during the design process significantly reduce the need for expensive rework during construction.

- Accelerated Construction: By minimizing on-site issues, construction can proceed more quickly, potentially allowing the project to be completed on time or even ahead of schedule.

- Enhanced Quality: Proactive clash detection ensures the precise and effective integration of various building systems, resulting in a higher-quality final product.

Real World Example: Jaguar Land Rover (JLR)

In the past, clashes arose throughout JLR’s rehabilitation projects. They started a digital twin project for their facilities in Slovakia and the UK to solve this. A thorough digital reproduction of a 9,000-square-metre assembly hall was produced by JLR, providing the basis for virtual-to-physical alignment.

For clash detection, this digital twin proved to be useful. Potential clashes were found early in the design process by superimposing suggested design components onto the virtual model. This saved JLR time, money, and resources by enabling them to make the necessary revisions before construction.

In addition, the digital twin expedited the verification of current facility conditions, simplifying the design procedure and lowering the requirement for on-site surveys. Because of this all-encompassing strategy for collision detection and facility comprehension, JLR is now at the forefront of the automobile industry’s digital revolution.

In addition to using the digital twin for clash detection, JLR also used it for site analysis, estimating building costs, and analysing the engineering budget in the pre-design stage. This all-encompassing strategy shows how digital twins may optimise the whole building lifecycle in a variety of ways.

JLR has demonstrated how proactive clash detection may result in considerable cost savings, increased project efficiency, and improved overall building performance by implementing digital twin technology.

Real World Example: Jaguar Land Rover (JLR)

In the past, clashes arose throughout JLR’s rehabilitation projects. They started a digital twin project for their facilities in Slovakia and the UK to solve this. A thorough digital reproduction of a 9,000-square-metre assembly hall was produced by JLR, providing the basis for virtual-to-physical alignment.

For clash detection, this digital twin proved to be useful. Potential clashes were found early in the design process by superimposing suggested design components onto the virtual model. This saved JLR time, money, and resources by enabling them to make the necessary revisions before construction.

In addition, the digital twin expedited the verification of current facility conditions, simplifying the design procedure and lowering the requirement for on-site surveys. Because of this all-encompassing strategy for collision detection and facility comprehension, JLR is now at the forefront of the automobile industry’s digital revolution.

In addition to using the digital twin for clash detection, JLR also used it for site analysis, estimating building costs, and analysing the engineering budget in the pre-design stage. This all-encompassing strategy shows how digital twins may optimise the whole building lifecycle in a variety of ways.

JLR has demonstrated how proactive clash detection may result in considerable cost savings, increased project efficiency, and improved overall building performance by implementing digital twin technology.

Empowering Operations & Maintenance with Digital Twins

By building digital twins of physical assets, operations and maintenance are being revolutionised. Unprecedented insights into asset performance and operational efficiency are provided by these virtual models.

- Predictive Maintenance: Digital twins can precisely forecast equipment faults by continually observing and evaluating real-time sensor data. By using a proactive strategy, planned maintenance interventions may be made, prolonging the asset’s lifespan, minimising unplanned breakdowns, and lowering operating expenses.

- Enhanced Operations: By offering a thorough understanding of asset performance, digital twins enable real-time monitoring, anomaly identification, and enhancement of performance. Organisations may optimise resource allocation, energy efficiency, and operational procedures by leveraging data-driven insights.

The Synergy: Design Informs Operations & Vice Versa

We have now understood how digital twins help in the design and maintenance individually, but the real strength of a digital twin lies in its capacity to close the gap between operation and design. A closed-loop system is created by digitally recreating a physical asset, such as a smart building, and updating it with real-time operating data. This makes it possible to optimise continuously, using operational data to inform the design of new initiatives.

To understand this better, let’s step inside a smart commercial complex:

Consider a sizable business structure that has a complete digital twin installed. The structural, mechanical, electrical, and plumbing systems are all included in this virtual model, along with information on occupancy, energy use, and environmental aspects.

- Driven by Operational Data, Design Optimisation

The digital twin of the building gathers a tonne of operational data, such as:

- Patterns of energy use: determining peak usage times, energy consumption of equipment, and energy loss via the building envelope.

- Examining how people walk, how much space they occupy, and what kinds of environments they like.

- HVAC system performance: Tracking humidity, temperature, and air quality to evaluate the comfort of occupants and system efficiency.

- Equipment failures: Monitoring equipment malfunctions and maintenance records to pinpoint dependability problems.

Which leads to benefits such as:

- Energy Savings: Research indicates that the use of digital twins in smart buildings can result in a 15-20% reduction in energy usage. This results in financial savings as well as a reduced environmental impact.

- Increases Productivity: By identifying and addressing possible equipment faults before they happen, predictive maintenance insights from the digital twin may assist save downtime and maintaining building systems. According to a McKinsey & Company research, predictive maintenance techniques can save downtime by as much as 30%.

- Improved Building Operations: Data-driven optimisation is made possible by real-time occupancy and environmental condition data analysis. This may result in better resource allocation, cleaner schedules, and occupant comfort, all of which can contribute to more economical and successful building operations

Facility managers can pinpoint areas for development and enhance forthcoming building designs by examining this data. For example:

- Energy efficiency: Future buildings can use passive cooling techniques or sophisticated HVAC systems with demand response capabilities if energy consumption analysis shows significant cooling loads during peak occupancy.

- Comfort of occupants: By studying occupancy trends, adaptable spaces that may change with demands can be designed with their wants in mind. For example, if data indicates frequent use of specific meeting rooms, future buildings can allocate more space for collaborative work areas.

- Equipment reliability: By identifying equipment with frequent failures, facility managers can select more robust and reliable components for future projects, reducing maintenance costs and downtime.

- Closed-Loop Computation

Using a closed-loop approach, future building designs incorporate operational knowledge back into the process of design. As an illustration:

- Data-driven design: To achieve the best energy performance, architects and engineers may utilise operational data to guide decisions about building orientation, glass choices, and HVAC system design.

- Performance-based design: Through an analysis of current building systems’ performance, designers may establish performance goals for the next projects and adjust their designs accordingly.

- Predictive maintenance: Choosing components with longer lifespans and built-in maintenance features might result from incorporating equipment failure data into the design process.

More creative, sustainable, and user-centred buildings result from this ongoing feedback loop between design and operation. Organisations may attain long-term operational excellence and optimise their real estate assets by harnessing the potential of digital twins.

Conclusion

The future of digital twins is incredibly promising. As technology advances, we can expect increasingly sophisticated digital twins capable of modelling complex systems and making autonomous decisions. By leveraging artificial intelligence and machine learning, digital twins will become essential tools for developing intelligent, sustainable, and resilient smart environments.

To fully realize the potential of digital twins, organizations need to invest in data infrastructure, develop digital twin expertise, and foster a culture of data-driven decision-making. By collaborating with Pratiti Technologies, you can:

- Create Immersive Digital Twins: We develop comprehensive virtual representations of your assets, capturing intricate details for precise analysis.

- Predict and Prevent: Utilize predictive analytics to anticipate equipment failures, reduce downtime, and optimize maintenance strategies.

- Optimize Operations: Gain real-time insights into resource allocation, energy efficiency, and overall performance.

- Inform Future Designs: Leverage operational data to enhance future designs, creating a continuous improvement cycle.

Partner with Pratiti Technologies to unlock the full potential of your assets through the power of digital twins. Contact us now.

After successful stint in a corporate role, Nitin is back to what he enjoys most – conceptualizing new software solutions to solve business problems. Nitin is a postgraduate from IIT, Mumbai, India and in his 24 years of career, has played key roles in building a desktop as well as enterprise solutions right from idealization to launch which are adopted by many Fortune 500 companies. As a Founder member of Pratiti Technologies, he is committed to applying his management learning as well as the passion for building new solutions to realize your innovation with certainty.