Table of Content:

Introduction

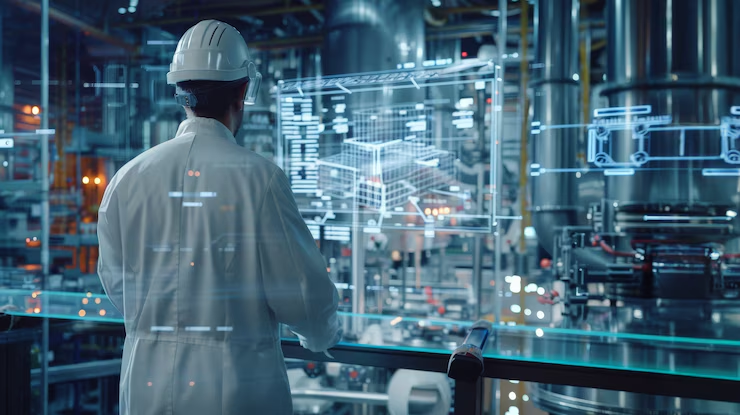

In today’s hypercompetitive industrial landscape, organizations are relentlessly pursuing ways to optimize performance, reduce costs, and innovate rapidly. One technology powering this transformation is the Digital Twin platform a sophisticated digital replica of physical assets, processes, or systems that enables real-time insights and predictive intelligence.

At Pratiti Technologies, our patented Digital Twin solutions empower enterprises across energy, manufacturing, infrastructure, and healthcare sectors to reimagine their operational models and unlock unprecedented value. This article explores how Digital Twin platforms are reshaping industrial performance, driving efficiency, agility, and innovation through seamless integration with IoT, AI/ML, and cloud technologies.

Digital Twin: The Heartbeat of Industry 4.0 Transformation

A Digital Twin acts as a dynamic virtual counterpart of a physical entity, continuously synchronized via real-time data streaming. It provides a persistent digital representation of the structure, behavior, and context of assets, enabling detailed monitoring, analysis, and simulation.

This fusion of physical and virtual worlds fuels Industry 4.0 initiatives the fourth industrial revolution characterized by smart automation, connectivity, and data-driven decision-making. By leveraging Digital Twin platforms, organizations can bridge the gap between operational realities and digital insights, fostering predictive maintenance, performance optimization, and risk mitigation.

Driving Value Across Industries

Manufacturing: Digital Twin in Manufacturing

In manufacturing, Digital Twin platforms serve as nerve centers for real-time asset monitoring and process optimization. Manufacturers leverage digital twins to simulate production lines, predict machine failures, and optimize workflows.

- Performance Monitoring: Continuous tracking of machine status, throughput, and energy consumption empowers manufacturers to identify bottlenecks and inefficiencies.

- Predictive Maintenance: By analyzing sensor data and historical trends, digital twins predict equipment failures before they happen, reducing downtime and maintenance costs.

- Quality Assurance: Simulations help maintain consistent product quality by enabling early detection of deviations and process anomalies.

For example, Pratiti’s manufacturing clients use digital twins to create virtual replicas of their shop floors, facilitating data-driven decision-making that improves overall equipment effectiveness (OEE) and reduces rework by up to 30%.

Energy and Utilities

The energy sector benefits from Digital Twin solutions that monitor power plants, renewable assets, and grid infrastructure.

- Asset Health Analytics: Real-time data from IoT sensors integrated with digital twins provide visibility into asset conditions, enabling optimized operations and longer asset life.

- Renewable Energy Optimization: Our patented digital twin platform for solar photovoltaic plants helps optimize asset performance, benchmark yields, and streamline operations and maintenance.

- Grid Balancing and Forecasting: Simulation capabilities allow energy companies to predict demand, manage load distribution, and reduce outages.

These applications contribute to sustainable energy production and efficient grid management, aligning with global ESG goals.

Infrastructure and Smart Cities

In infrastructure management and smart cities, Digital Twin platforms enable comprehensive monitoring and simulation of complex systems such as buildings, transportation networks, and utilities.

- Building Management: Digital twins support smart HVAC control, energy efficiency optimization, and occupancy analysis in green buildings.

- Urban Planning: Virtual replicas of city infrastructure facilitate scenario testing for disaster preparedness, traffic management, and resource allocation.

- Operational Efficiency: Predictive analytics help reduce maintenance costs and extend the life of critical infrastructure.

Pratiti’s smart building customers leverage digital twin insights to reduce energy consumption by 30–40%, demonstrating significant cost savings and sustainability impact.

Healthcare

In healthcare, Digital Twin solutions are transforming patient care and operational efficiency.

- Patient Monitoring: Virtual models of medical devices and patient health parameters enable real-time tracking and proactive interventions.

- Personalized Treatment: Simulations of physiological responses help tailor treatments for chronic disease management.

- Operational Analytics: Hospitals optimize equipment usage and streamline workflows through digital twin-enabled insights.

These innovations enhance patient outcomes while improving resource utilization across healthcare facilities.

The Technology Backbone: Integration with IoT, AI/ML, and Cloud

Pratiti’s Digital Twin platform excels through deep integration with IoT devices, advanced AI/ML algorithms, and scalable cloud architectures.

- IoT Connectivity: Sensors and devices continuously feed real-time data into the digital twin, ensuring accurate, up-to-date virtual representations.

- AI and Machine Learning: Advanced analytics identify patterns, detect anomalies, and generate predictive insights that drive proactive decision-making.

- Cloud-Native Design: Our platform supports scalable deployments and seamless integration with enterprise systems, ensuring accessibility and security.

This technical strength enables organizations to operationalize digital twins effectively, unlocking benefits like reduced downtime, improved asset reliability, and accelerated innovation.

Why Choose Pratiti’s Digital Twin Solutions?

- Patented Technology: Unique digital twin IP optimized for renewable energy, manufacturing, and infrastructure sectors.

- Cross-Industry Expertise: Deep domain knowledge coupled with advanced analytics capabilities.

- Customizable and Scalable: Tailored solutions designed for diverse business needs and integration with existing IT ecosystems.

- Proven Impact: Real client success in enhancing OEE, energy efficiency, predictive maintenance, and customer satisfaction.

Conclusion: Transforming Industrial Performance with Digital Twins

As industries worldwide accelerate their journey towards digital transformation, Digital Twin platforms stand out as vital enablers of innovation and operational excellence. By providing rich, actionable insights into physical assets and processes, they empower enterprises to anticipate challenges, optimize performance, and drive sustainable growth.

Pratiti Technologies is proud to be at the forefront of this revolution, delivering cutting-edge Digital Twin solutions in India, UAE, and USA that unlock the full potential of Industry 4.0.

If you’re ready to reimagine your industrial performance and embrace a future powered by digital twins, explore how Pratiti’s platform can be your trusted partner on this journey.

Let’s revolutionize your business operations with Digital Twin technology unlocking new levels of efficiency, insight, and innovation.

For more information or to start a conversation, reach out to us at insights@pratititech.com.

After successful stint in a corporate role, Nitin is back to what he enjoys most – conceptualizing new software solutions to solve business problems. Nitin is a postgraduate from IIT, Mumbai, India and in his 24 years of career, has played key roles in building a desktop as well as enterprise solutions right from idealization to launch which are adopted by many Fortune 500 companies. As a Founder member of Pratiti Technologies, he is committed to applying his management learning as well as the passion for building new solutions to realize your innovation with certainty.